Project overview

Despite more than 200 years of development of batteries, the physical limits of battery performance are far from being reached. The complexity of physico-chemical processes inside batteries makes any development strongly dependent on a proper description and monitoring of the inherent evolution and interaction of all materials involved in the functioning of an electrochemical cell. The mean figures of merit (specific energy per mass, volume or cost unit, cyclability) can all theoretically be substantially improved, under the condition of a proper understanding of where and how their limits are reached in today’s industrialized systems. This underlines how much this important branch of our technological future depends on novel and accessible characterization techniques. Given this grand challenge, access to advanced characterisation solutions for the EU industry will be key to accelerate innovation and reduce the large cost share of materials. However, several bottlenecks are preventing access by companies to novel techniques, to which TEESMAT – by launching an Open Innovation Test Bed (OITB) – brings a comprehensive response by leveraging European strengths from 11 Countries and facilitating access to physical facilities, capabilities and services implementing novel characterisation solutions with outstanding capability and performance.

Objectives:

The overall aim of TEESMAT is to lower the barriers of access to industrially relevant, novel problem-solving techniques and services, including characterisation and data analytics for large and small companies. This aim will be pursued by setting up & implementing a financially sustainable Open Innovation Test Bed (OITB) whose techniques and services address such diverse problems faced in the development of clean, safe, high-performance battery solution. The three core objectives of TEESMAT are:

- Set-up an OITB to provide effective, centrally managed access to advanced materials’ characterisation, modelling and data informatics;

- Demonstrate the OITB’s added value by solving persistent, high-impact industrial problems;

- Ensure the OITB’s growth, longevity, financial sustainability and stakeholder support.

Consortium

The TEESMAT consortium gathers 9 Service Providers (SEMILAB, INCORE, CERTH, CEA, ZSW, VITO, ESRF, TECNALIA, SERMA) developing services with the active contribution of 10 Services Users (ZINERGY, LITHOPS, YUNASKO, GENES’INK, SUNLIGHT, NORTHVOLT, ARKEMA, UMICORE, CEGASA and CRF-FIAT) sharing materials characterisation experience in the frame of 24 User Access Cases. TEESMAT is managed and coordinated by CEA and WAVESTONE. EBN is taking in charge communication and dissemination tasks and activities. A total of 14 small and large enterprises from 10 Countries contribute on both sides of the service (offer and demand) along the full value chain. The consortium is offering a complete set of interdisciplinary skills extremely interconnected and transverse for the project.

During project lifetime, the consortium aims at attracting additional EU Services Users and Providers in order to widen the OITB experience and prepare its continuity beyond TEESMAT.

GenesInk role and expectations

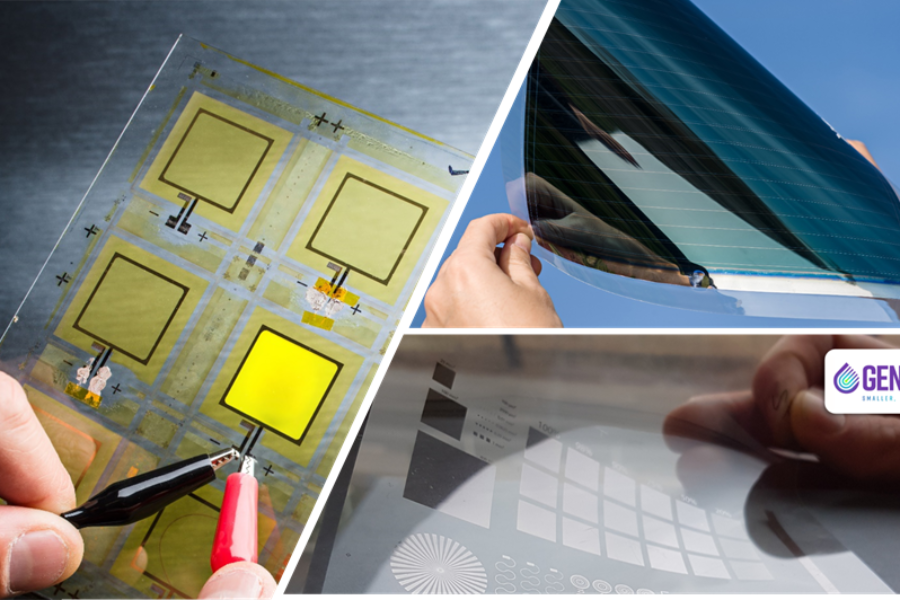

GenesInk participates to TEESMAT as a service user. In the framework of TEESMAT, GenesInk is seeking for solutions and answers related to “All printed batteries user case”.

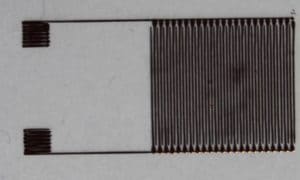

Indeed, GenesInk is developing 2 solutions for Cu metallisation of polymer flexible substrates – electroless metallisation and Cu nanoinks. Cu will be integrated as current collector into printed flexible batteries. Cu is subject to oxidation during processing (deposition and curing). Besides, storage of Cu is a tough task due to oxidation and nanoparticles (NPs) aggregation. Tools are required to follow copper oxidation in liquid phase during storage and inline during processing (deposition and curing). Furthermore, tools are needed to study the quality of the deposited Cu ink and control all defects caused by oxidation and/or contamination by battery layers (electrodes, electrolytes, etc.).