Electronics is one of the industrial sectors with the greatest impact on the environment in terms of CO2 emissions and waste. Since 2020, the government « France Relance » plan has been

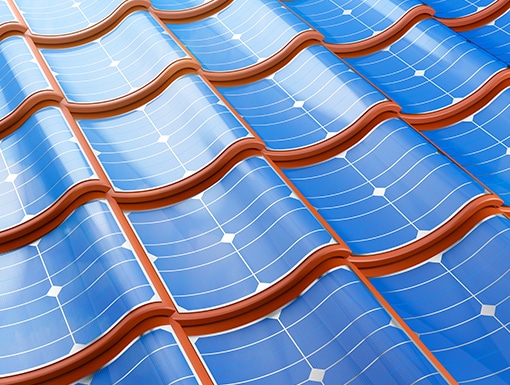

Organic solar cells show great potential due to their low production costs and mechanical flexibility. These characteristics open up a new range of solar cell applications.

With the emergence of flexible OPVs (for installation on windows, roofs or even in personal belongings) or flexible displays, ITO films are no longer relevant since this material is brittle. GenesInk TranDuctive® is a wet solution printable with standard coating processes and compatible with plastic substrates thanks to its low drying temperature, enabling flexible device manufacturing.

Transparent conductive films must have low roughness to obtain a flat interface between the film and other layers in order to reach superior performances. Roughness below 10 nm is made possible when using TranDuctive® coated films.

For the implementation and mass dissemination of organic solar cells, manufacturing costs, efficiency and long-term stability are crucial. GenesInk solutions are perfect for large area panels in educational establishments or public spaces, which require low sheet resistance.

The production of organic solar cells using solution-based manufacturing processes requires materials such as printable inks which have to meet the following requirements:

– fit with industrial manufacturing processes

– offer higher solar cell efficiency

– available in large amounts of high-quality product

Our HeliosInk product line covers most of the technologies that are required to manufacture thin, semi-transparent and flexible organic solar cells, from electrodes to charge transport layers.