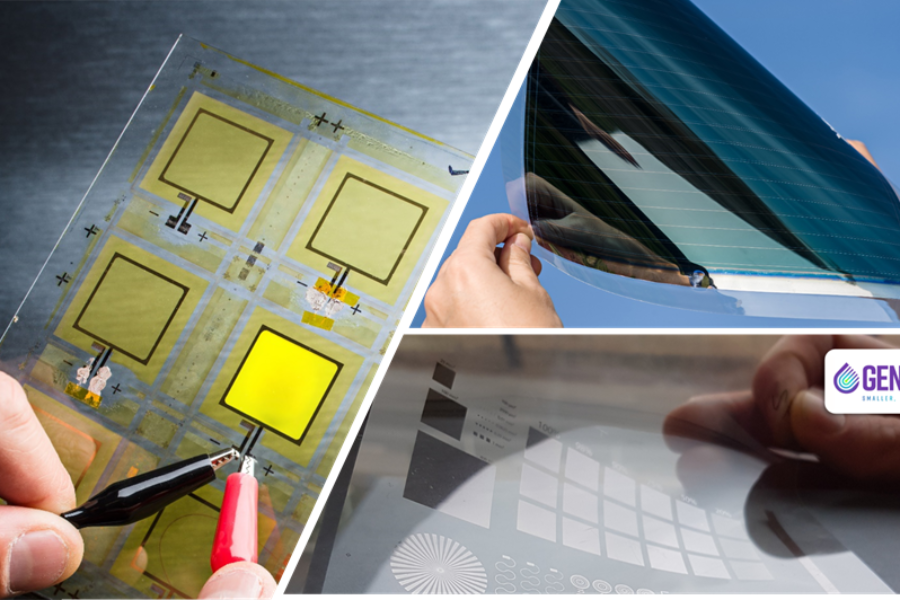

OLED Diplays are being integrated into a motorcycle jacket. This improved visibility increases driver safety. The use of the roll-to-roll process for OLED production promises a considerable reduction in production costs. This work is done in the frame of the EU-funded PI-SCALE project which is focusing on various applications of OLEDs, including their integration into textile designs.

The technology involves « fabricating the OLEDs on flexible substrates such as plastic films and connecting them to conductive threading for their supply of electrical power. » Quoted in the press release, Claudia Keibler-Willner, head of department at the Fraunhofer FEP, summarises the outcome: « We have taken a major step forward in economical fabrication processes for OLEDs. The results are impressive: the OLED shines very uniformly. » She adds: « The use of the roll-to-roll process also promises considerable cost reductions for future components. By combining printed and vaporized layers, process throughput and production speed can be increased up to 100 times. »

read more at: phys.org